WEINIG finger jointing lines: The fastest way to create higher value

Finger jointing is recognized as the most stable method of wood length joints. And if you require this technology, there's no better exponent than WEINIG. We are the specialists and have been number 1 on the market for over 25 years. WEINIG finger jointing technology is focused on maximum precision. This means minimal dimensional allowance, wood losses and operating costs. All systems are extremely user-friendly. This makes residual wood processing and upgrading by finger jointing profitable and easy for you!

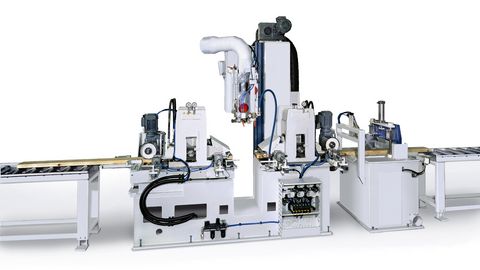

The flexible modular design allows machines to be equipped according to your individual requirements. This enables high flexibility for standardized as well as customer-specific solutions, regardless of whether the systems have raw wood entry lengths, smaller or larger than 1,000 mm. The principle can be used for all performance classes: From the ProfiJoint entry model to the Ultra, CombiPact and Turbo-S models up to the high-performance class with the HS120 and HS200 horizontal finger jointing lines. In short: WEINIG system concepts are designed to meet the highest demands in quality for all performance classes.

威力短料指接生产线

进料速度从 6 m/min 到 70 m/min

- 指接型面适用于所有领域

- 最大的指接精度和稳定性

- 性能稳定强大

- 高产能,可达200块/分钟(28千米/8小时-班)

- 操作方便简单

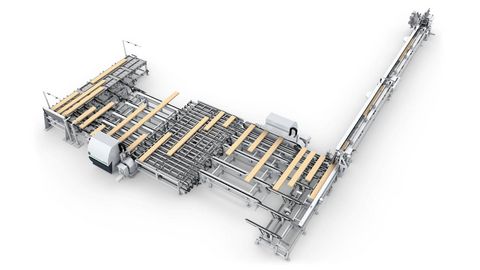

威力木结构材指接生产线

进料速度可达 120 m/min

- 可进行垂直和水平指接

- 进料长度可达2米,3米,4米,甚至6米

- 铣齿高度可达(木料宽度)300mm

- 所有类型的胶黏剂均可使用

- 端头压机、滚压机、周期压机或者连续通过式压机均可使用

威力紧凑型指接生产线

威力单根木料指接生产线

威力连续通过式接长压机